Bathtubs do not enhance the beauty of the bathroom, but with the same its usability and cost matters too. There are many different types of Bathtubs available in the market which are made with different types of material and differ in price too.

Therefore, there are many features that affect the price and quality. Also the selection of a bathtub material is very important as how and where it is to be used? Bathtubs are often used for the ultimate relaxation,

however, if the tub is not appropriate it can be a complete stress. There is a wide array of bathtub materials, dimensions and shapes available today so better to check pros and cons of each material type to get a better and clearer picture of each so you can choose the perfect bathtub for your home and lifestyle.

There are many different materials used to construct Bathtubs; all having their own pros and cons as per properties of material being used. Acrylic, Fiberglass, Solid-Surface, Cast Iron, Cultured Marble, Ceramic Tile, Stone and Wood are few materials that has been used so far.

Porcelain Enameled Steel Bathtubs

One the most common type is Porcelain-enameled steel and often an inexpensive option for many. It is made of steel sheeting and is coated with porcelain enamel to give it a finish look. Though this tub is heavier than acrylic or fiberglass but not as heavy as the old-fashioned enameled cast iron which were used in old times.

Pros:

- Very affordable and cost effective

- Relatively lightweight than cast iron

- Easily available in standard sizes (60 x 30 inches)

- Durable and long lasting

- Easy to clean and maintain.

Cons:

- The surface can chip when heavy objects are dropped

- If there is a chip, rust tends to form

- Limitation for options for color and shape

- Insulation is a must, else it’s noisy.

- Loses heat quickly

Acrylic Bathtubs

Acrylic Bathtubs are a very popular and most wanted among the homemakers due to their versatility, wide range of options, durability and most important its low cost. Vacuum-formed acrylic sheets are reinforced with fiberglass to construct Acrylic Bathtubs. Due to its lightweight it’s easy to install Acrylic tubs.

Pros

- Lightweight and easy to handle.

- Affordable and cost effective

- Available in many colors, shapes, and sizes

- Durable and repairable surface

- Non-porous surface makes it bacteria free.

Cons:

- The surface can damage and scratch if cleaned with abrasive cleaners or metallic objects.

- Proper reinforcement of stress points is must during installation

- Acrylic is more expensive and costly as compared to fiberglass

Fiberglass (FRP) Bathtubs

Fiberglass is another popular and affordable material used to construct bathtubs. These type of tubs are made of layers of surface coat and polyester resin. Also fiberglass reinforcement is done on tubs. Though fiberglass tubs are not very expensive and cheaper in terms of price than acrylic but are also less durable as compared to acrylic tubs.

Pros:

- Installation is easy

- Light in weight

- Very inexpensive

- Easy cleaning and maintenance

- Easy repairable surface

- A great option for a shower/tub combination

Cons

- Less durable if compared to other materials

- The surface can easily crack and scratch

- With passage of time its finish tends to fade and gets dull.

- Color options are limited.

Enameled Cast Iron Bathtubs

A very durable and classic bathtub material, enameled cast iron Bathtubs are long lasting but the only issue is its weight and being very heavy. Since the tub is made of molded iron coated with porcelain enamel it gives a quality and higher end option among selection of bathtubs. The only visible disadvantage is its weight.

Due to its heavy weight it becomes difficult to install and sometimes requires structural reinforcement of the floor.

Pros

- Excellent heat retention

- Very durable and long lasting

- Thick enamel coating helps it resist to chip and scratch

- Can be easily resurfaced

- Classic look

- Large range of color choices available

Cons

- Very heavy in weight.

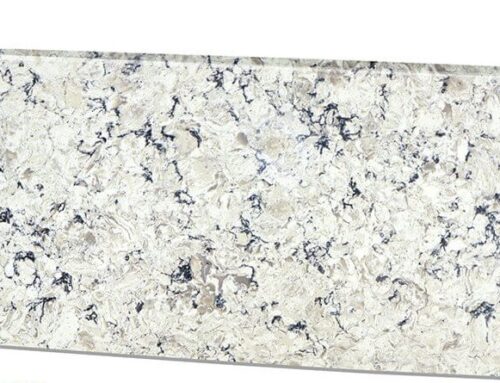

Cast Polymer (Cultured Marble, Granite, or Onyx)

The most wanted and in demand in the modern age are the cast polymer bathtub materials. They include engineered natural stones and solid surface materials.

These beautiful Bathtubs are casted by molding together some minerals, polymeric materials, and resins to form a solid material which is similar to solid-surface countertops used in modern bathrooms and kitchens and interior surfaces. E.g. Corian material. The tubs are duly finished with a gel-coat finish to give it a perfect look.

Pros

- Trendy and easy to clean

- Very much affordable

- Many color options and shapes available.

- In case of scratches on the surface it can be easily buffed out

- More Hygienic and Stain-resistant.

Cons

- Can be brittle with rough use.

- Gel coat may weary and can lead to unrepairable cracks

Conclusion

Bathtub materials affect the look and feel of the entire bathroom ambiance. Its weight, heat retention quality, cleanliness, hygiene and maintenance are important features that one considers before buying one and its price does matter.

Since tubs are usually once in a lifetime installed and not easy to replace, it is important to know that they are durable and pay a long lasting value. The properties of material is very important to consider as it helps you evaluate its durability and lasting value.

Since many materials are available in the market it’s important to consider all features and properties and also the cost effectiveness so the bath tubs manufactured are market competitive and durable as well.

With the change in trends and advancement in technology and modern lifestyle, Opaly Quartz solid surface is considered to be the ideal material used in bathtub manufacturing worldwide.